LFA 427 NETZSCH.

A device for measuring the thermal diffusivity of materials using the Laser Flash technique. This device sending a laser pulse to the test sample and measuring its temperature with the IR sensor on the other side. The following materials can be tested in the LFA 427: ceramics, glass, metals, liquid metals and liquids (placed in a special tank), powders, fibers and composites.

DSC 8000 ParkinElmer. Differential scanning calorimeter.

The device is used to determine the temperature and thermal effects of endothermic and exothermic changes of various types of chemical reactions and phase changes.

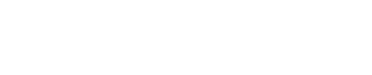

Unitherm Model 2022.

The device is used to measure the thermal conductivity of materials such as polymers, ceramics, composites, glasses, rubber, some metals and other materials with low thermal conductivity. Pastes and liquids can also be used using a special container. Thermal conductivity range: 0.1 to 40 W/(mK).

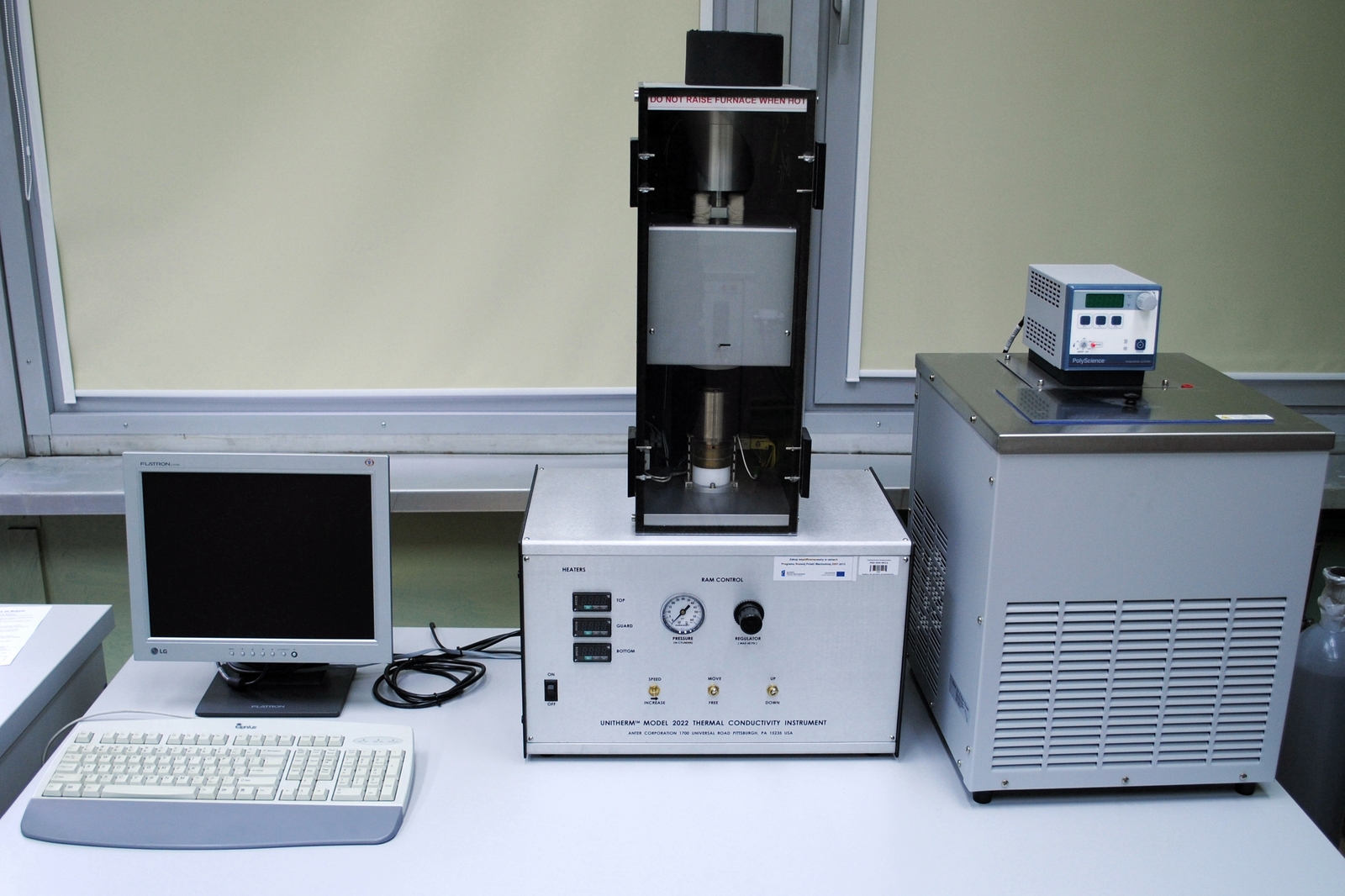

KD2 PRO thermal properties analyzer.

The KD2 PRO thermal properties analyzer is a hand-held, portable meter for measuring thermal properties of soils, solids, semi-liquid and liquid materials. The set consists of a control console and sensors that are inserted into the tested material. Single-needle sensors are used to measure conductivity / thermal resistance. The two-needle sensor measures conductivity, thermal resistance, specific heat and thermal diffusivity.

Laboratory for measuring the thermal conductivity of metals and alloys.

One of the unique methods of measuring the thermal conductivity of metals and alloys is the quasi-stationary method in which the phase transition is used. It is a method that belongs to the non-stationary absolute methods of measuring thermal conductivity. The measurement method is based on the fact that the test sample is placed vertically between the thermodes. A heat flux flows from the upper thermode (heater), which causes an increase in the temperature of the sample and the lower thermode. This process continues until the melting point of the metal (metrological substance) contained in the lower thermode is reached. The temperature is established at the lower thermode and along the sample for the period of time during which the metrological substance undergoes a phase change. In this state, known as the quasi-steady state, the thermal power flowing to the lower thermode is determined by the mass of the metrological substance and the time of the quasi-stationary temperature stop. The knowledge of the measured temperature drop and thermal power allows to determine the thermal conductivity coefficient of the tested sample.

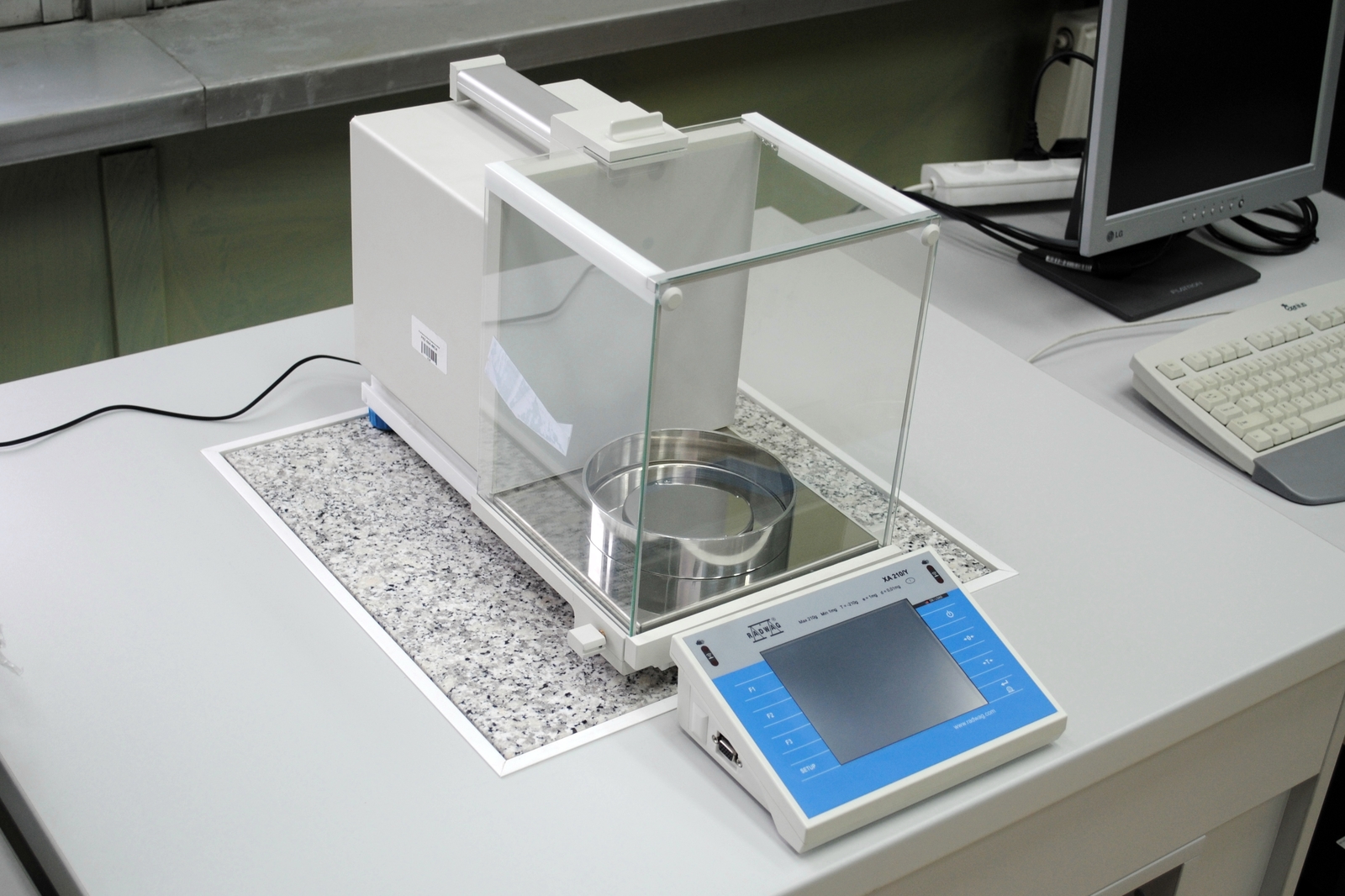

XA 210/Y Micro Balance.

The balance is used for laboratory measurements of fuel samples, samples for measuring thermal diffusivity and thermal conductivity. Technical data: maximum load 210 g,minimum load 1 mg, reading accuracy 0.01 mg.